Tanzania drip coffee packaging machine for Kilimanjaro coffee, etc., cities: Arusha, Babati, Bagamoyo, Biharamulo, Bukoba, Chake Chake, Chunya, Dar es Salam, Dodoma, Geita, Handeni, Iringa, Isoko, Kahama, Kasanga, Kasulu, Kibaya, Kibondo, Kidika, Kigoma, Kilindoni, Kilosa, Kilwa Kivinje, Kilwa Masoko, Kipili, Kitodi, Kitunda, Koani, etc. Filter coffee powder packaging machine, nitrogen filled to keep fresh!

Coffee history states that coffee was introduced to Tanzania from Ethiopia in the 16th century. The Haya people brought “Haya Cofffee” or “amwani” to Tanzania, which was probably the Robusta variety, and coffee has been an integral part of local culture ever since. The ripe coffee berries are boiled, smoked and roasted for several days, and then chewed rather than brewed as coffee.

Coffee first became a cash crop in Tanzania during the German colonial period. In 1911, the colonial government ordered the planting of Arabica coffee trees in the Bukoba region, but the planting method was different from the traditional practice of the Haya people, so the Haya people were reluctant to replace food crops with coffee trees. Despite this, coffee production in the area has increased. Other areas in the country are less familiar with coffee cultivation and therefore have less opposition. The Chagga tribe living around Mount Kilimanjaro switched all their crops to coffee after the Germans banned the slave trade.

After World War I, management of the area was transferred to the British. They planted more than 10 million coffee plants in Bukoba, but also clashed with the Haya people, often resulting in the uprooting of the plants. As a result, the coffee industry did not develop significantly compared to Chagga.

The first cooperative was established in 1925, called the Kilimanjaro Native Planter’s Association (KNPA). This was the first of several cooperatives, and producers under it had more freedom to sell directly to London, thereby obtaining higher prices.

After Tanzania’s independence in 1961, the government focused on the coffee industry, attempting to triple coffee production by 1970; however, this plan was not achieved. After a period of slow industry development, high inflation and economic depression, Tanzania became a multi-party democracy.

In the early and mid-1990s, a series of reforms were made to the coffee industry. Coffee producers were allowed to sell more directly to buyers, rather than all through the National Coffee Marketing Board. The coffee industry was hit hard in the late 1990s when coffee blight spread across the country, decimating trees north of the border with Uganda. Today, Tanzania’s coffee production is 70% Arabica and 30% Robusta.

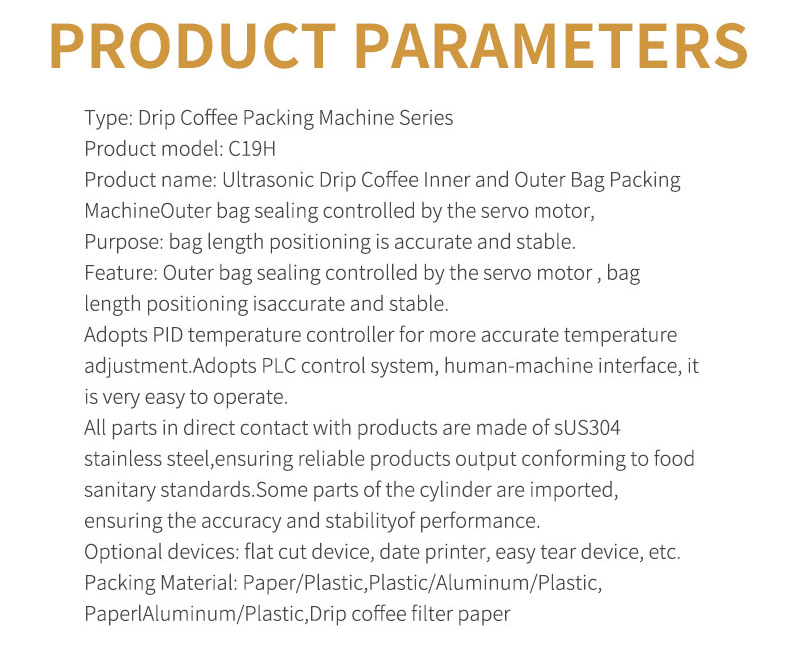

Type: Drip Coffee Packing Machine Series

Product model: C19H

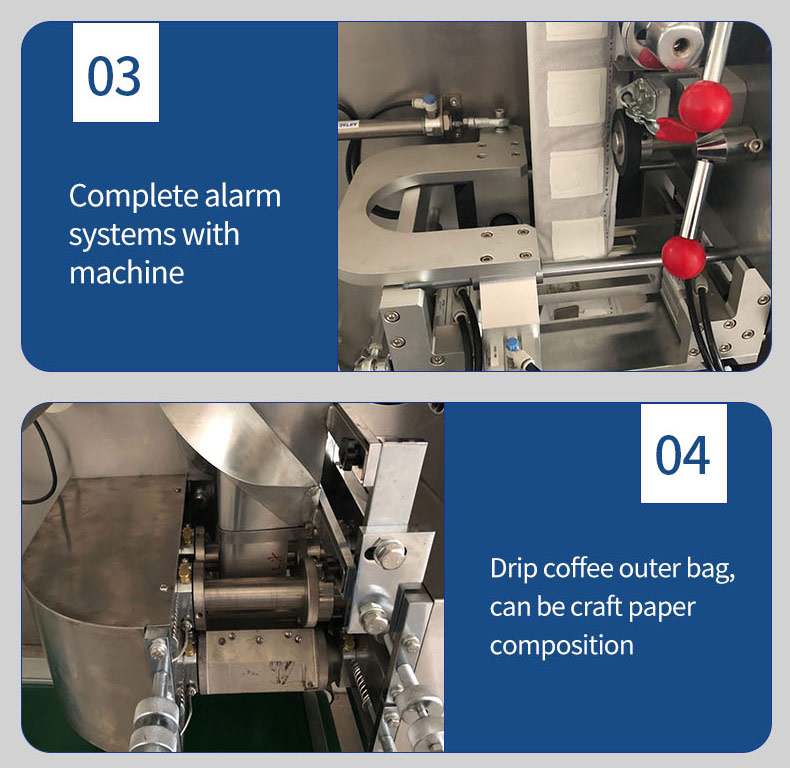

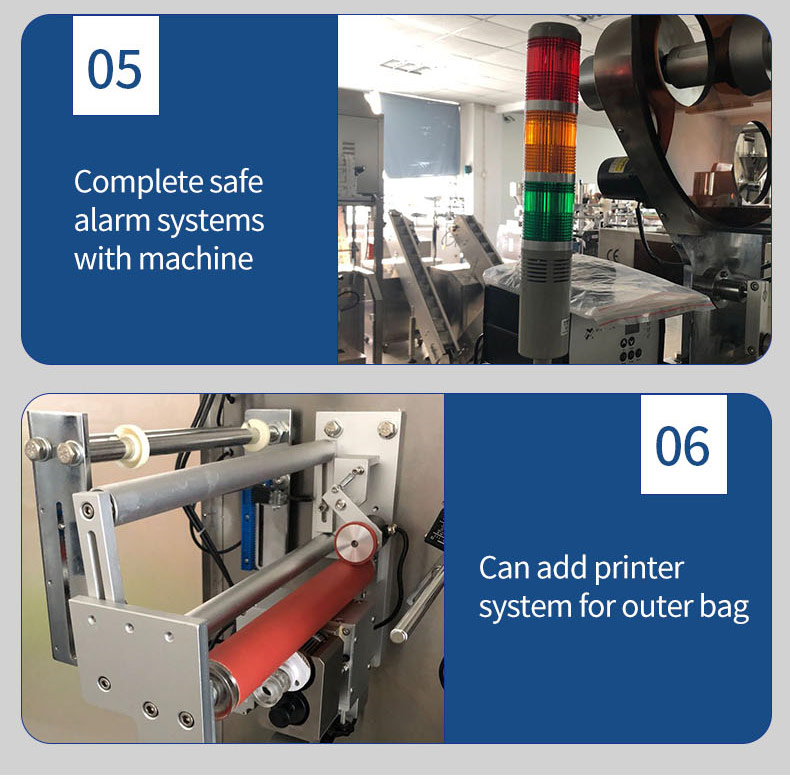

Product name: Ultrasonic Drip Coffee Inner and Outer Bag Packing MachineOuter bag sealing controlled by the servo motor,

Purpose: bag length positioning is accurate and stable.

Feature: Outer bag sealing controlled by the servo motor , bag length positioning isaccurate and stable.

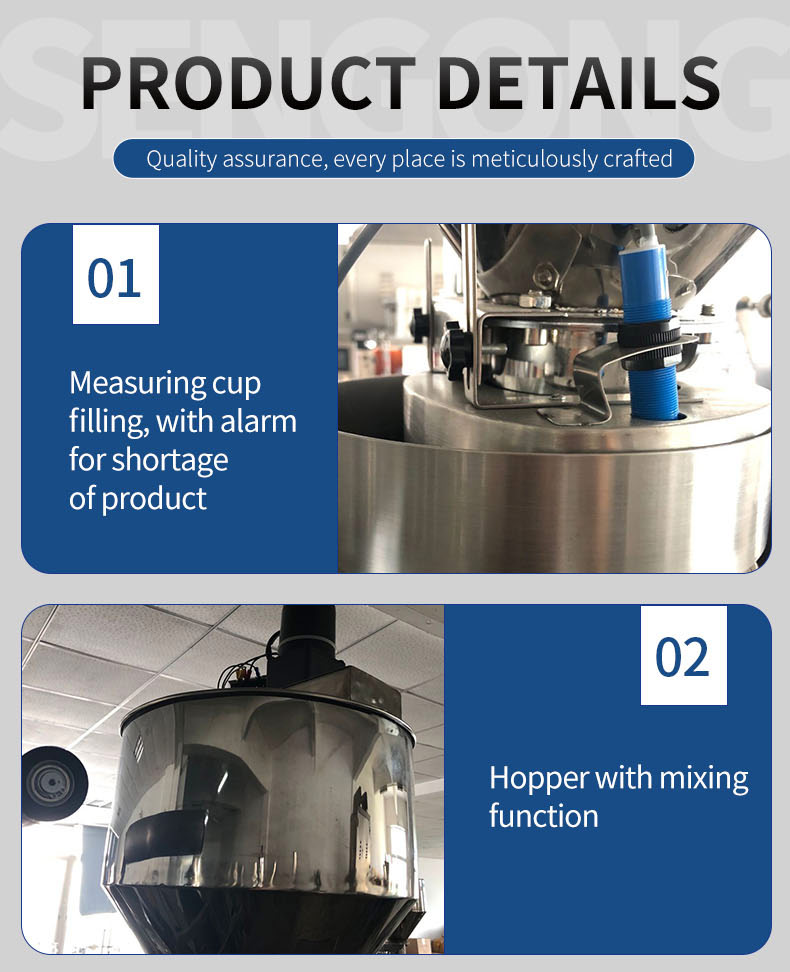

Adopts PID temperature controller for more accurate temperature adjustment.Adopts PLC control system, human-machine interface, it is very easy to operate.

All parts in direct contact with products are made of sUS304 stainless steel,ensuring reliable products output conforming to food sanitary standards.Some parts of the cylinder are imported, ensuring the accuracy and stabilityof performance.

Optional devices: flat cut device, date printer, easy tear device, etc.

Packing Material: Paper/Plastic,Plastic/Aluminum/Plastic,PaperlAluminum/Plastic,Drip coffee filter paper

Bag type: 3 side sealing

Outer Bag size: L:85~120mm,W:75~100mm (Film width200mm, Bag size: 120*100mm)

lnner Bag size: L:50~75mm, W:50~90mm (Filter paperwidth 180mm, Bag size: 90*74 mm)

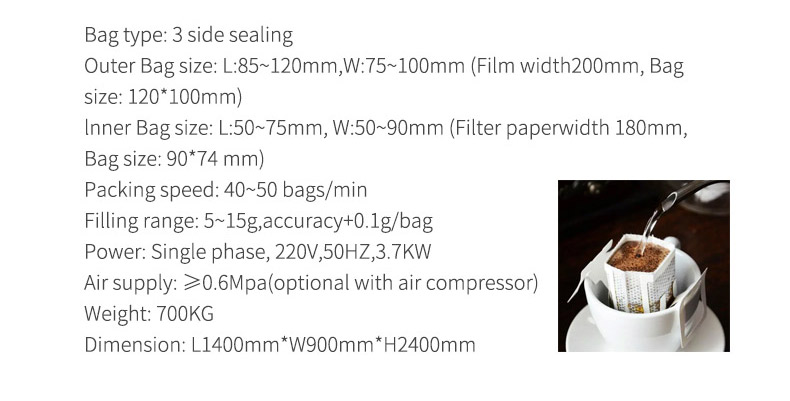

Packing speed: 40~50 bags/min

Filling range: 5~15g,accuracy+0.1g/bag

Power: Single phase, 220V,50HZ,3.7KW

Air supply: ≥0.6Mpa(optional with air compressor)

Weight: 700KG

Dimension: L1400mm*W900mm*H2400mm

Tanzania drip coffee bag packaging machine