How to Brew Teabags Properly

1. Inject water first, then throw tea bags

Maybe you think that brewing is no different from ordinary green tea, just put the tea bag in the cup and pour boiling water directly. It’s not that simple, because the teabag contains air, and doing so will cause the teabag to float, causing the tea flavor to filter out unevenly. The cup should be filled with boiling water about 80% full before putting in the tea bag.

2. The tea bag sinks to the bottom, control the time

Gently put the teabag into the cup filled with boiling water, wait quietly for the teabag to sink to the bottom of the cup, and you can see the color change of the tea soup. At this time, you can gently lift the small rope holding the tea bag with your hand, so that the tea flavor will slowly seep out as you lift and release.

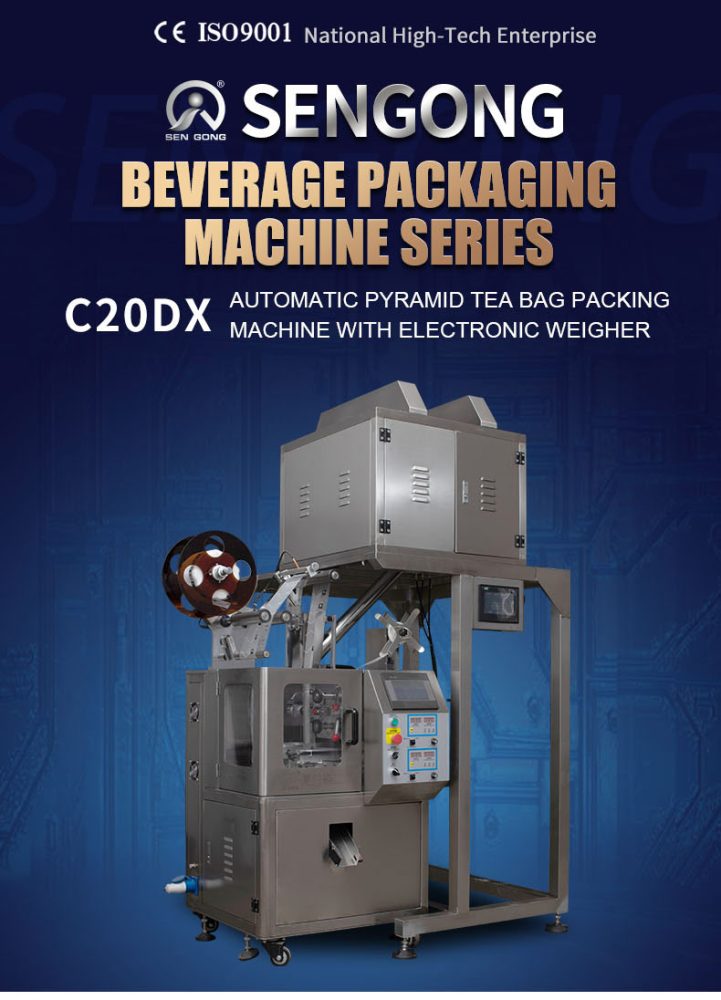

Triangle nylon tea bag packing machine with outer envelope

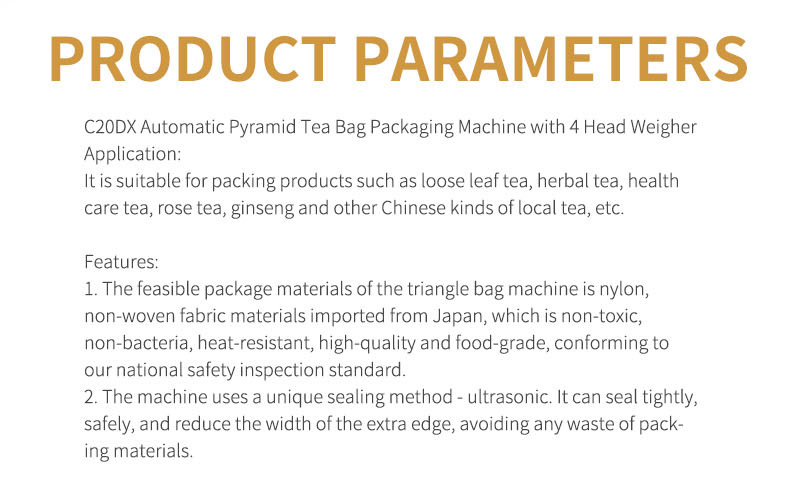

C20DX Automatic Pyramid Tea Bag Packaging Machine with 4 Head Weighs

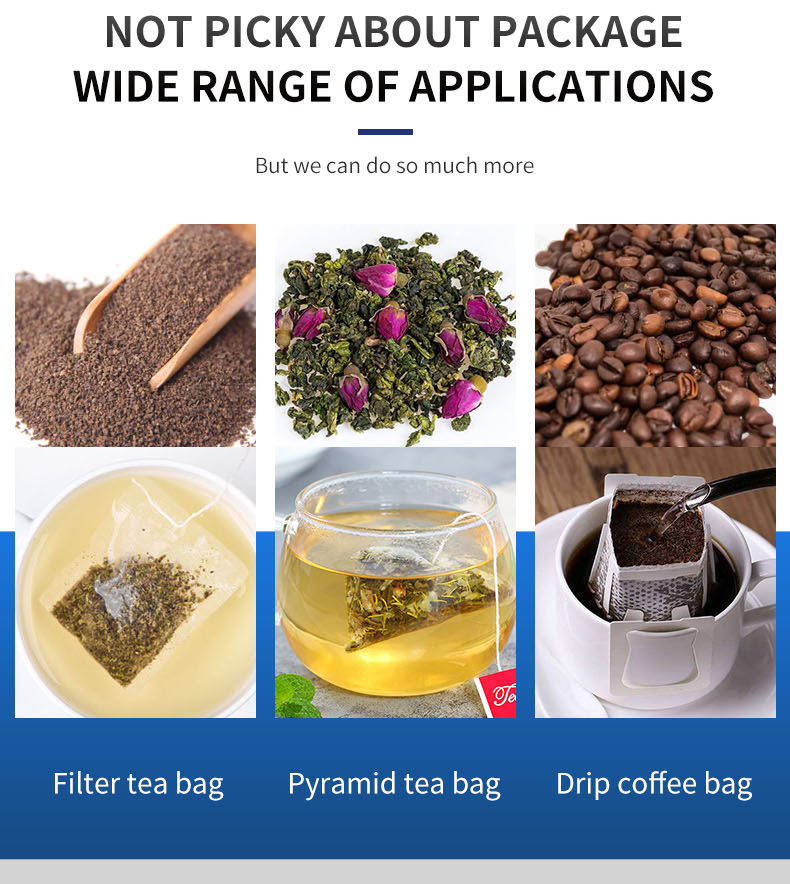

Application:

It is suitable for packing kinds of teas such as loose leaf tea like black

tea and oolong tea, herbal tea, health tea, rose tea, jasmine tea,

etc.Features:

1. The feasible package materials of the triangle bag machine is nylon,

PLA, non-woven fabric materials imported from Japan, which is non-toxic,

non-bacteria, heat-resistant, high-quality and food-grade, conforming to

our national safety inspection standard.

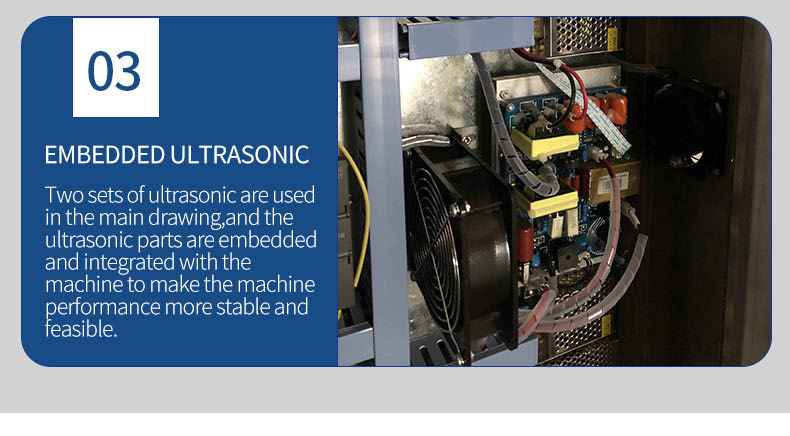

2. The machine can uses a unique sealing method – ultrasonic. It can seal

tightly, safely, and reduce the width of the extra edge, avoiding any waste

of packing materials.

3. The machine can switch the bag shape between pyramid(triangle) and flat

(rectangle), and also the sealing method can be switched into back sealing.

4. The machine can be linked with the outer pouch packing machine.

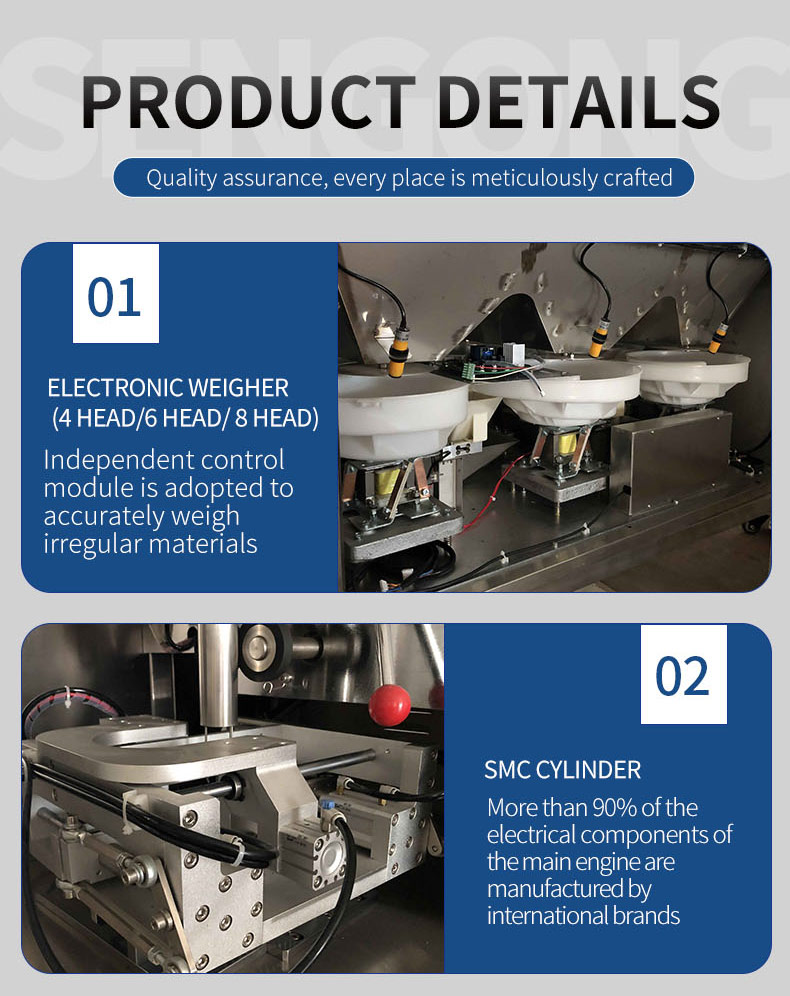

5. Each electric scale of this machine is independent, each one can be

operated alone.

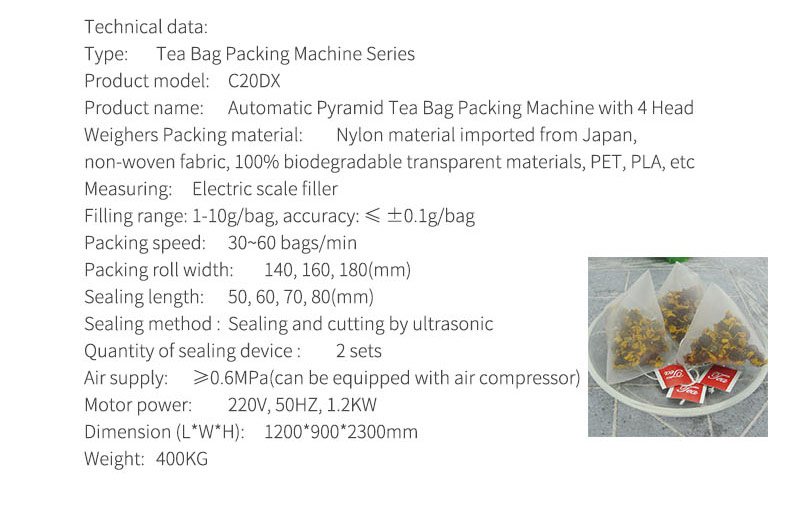

Technical data:

Machine type: Tea Bag Packing Machine Series

Machine model: C20DX

Machine name: Export-oriented Automatic Pyramid Tea Bag Packing Machine

with 4 Head Weighs(Improved)

Packing material: Nylon material imported from Japan, non-woven fabric,

100% biodegradable transparent materials, PET, PLA, etc

Measuring method: Electric scale filling

Filling range: 1-10g/bag, accuracy: ≤ ±0.1g/bag

Packing speed: 30~60 bags/min

Packing roll width: 120, 140, 160(mm)

Sealing length: 50, 60, 70, 80(mm)

Sealing method : Sealing and cutting by ultrasonic

Qty of sealing device : 2 sets

Air supply: ≥0.6MPa(can be equipped with air compressor)

Motor power: 220V, 50HZ, 1.2KW

Dimension: 1800*900*2500mm(L*W*H)

Machine weight: 600KG