### Detailed Analysis of Cuban Coffee and Drip Coffee Packaging Machines

#### I. Overview of Cuban Coffee

1. **Origin and Characteristics**

– Cuba, located in the Caribbean region, has unique climatic and soil conditions that are ideal for coffee cultivation. Cuban coffee is renowned for its rich flavor and low acidity, earning it a prestigious reputation in international markets.

– The primary coffee variety grown in Cuba is Arabica, known for its high quality and complex flavor profile.

2. **Cultivation and Processing**

– Cuban coffee cultivation is concentrated in eastern regions such as Santiago Province. The high altitude and volcanic soil in these areas provide an excellent environment for coffee growth.

– The processing involves steps such as harvesting, fermentation, washing, and drying, ensuring the quality and flavor of the coffee beans.

3. **International Market Status**

– Cuban coffee is considered a premium product globally, often used in specialty and gourmet coffee shops. Brands like “Cafetal” hold significant recognition in international markets.

#### II. Features and Functions of Drip Coffee Packaging Machines

1. **Working Principle**

– Drip coffee packaging machines precisely control temperature and time to evenly drip hot water over coffee grounds, extracting a concentrated coffee liquid. This method effectively preserves the flavor and aroma of the coffee.

2. **Packaging Technology**

– These machines typically feature advanced sealing techniques to ensure the packaged coffee remains fresh during its shelf life. Common packaging forms include vacuum sealing and nitrogen flushing, which extend the product’s freshness.

3. **Machine Types**

– **Home Use**: Suitable for individuals or small families, these machines are easy to operate and reasonably priced.

– **Commercial Use**: Designed for cafes and production lines, these machines offer higher efficiency and automation.

4. **Advantages and Limitations**

– **Advantages**: The gentle extraction process retains the coffee’s flavor well; simple operation makes it suitable for various settings.

– **Limitations**: Compared to other extraction methods (e.g., espresso), drip machines may have limitations in extraction speed and concentration.

#### III. Combining Cuban Coffee with Drip Coffee Packaging Machines

1. **Flavor Expression**

– The drip extraction method can fully showcase the rich taste and complex flavors of Cuban coffee, appealing to consumers seeking a high-quality coffee experience.

2. **Packaging Solutions**

– Using drip packaging machines ensures Cuban coffee maintains its optimal state during packaging, extending its freshness and meeting diverse market demands.

3. **Market Applications**

– In the premium coffee market, the combination of Cuban coffee with drip packaging technology enhances product value, attracting consumers who prioritize quality.

#### IV. Purchase and Usage Recommendations

1. **Purchase Suggestions**

– **Capacity and Purpose**: Choose a machine based on your needs, with home models typically handling 1-2 cups and commercial models offering larger capacities.

– **Brand and Quality**: Opt for reputable brands to ensure reliability and good after-sales service.

– **Additional Features**: Consider features like timers and temperature adjustments to enhance convenience.

2. **Usage Tips**

– **Coffee Bean Selection**: Prioritize freshly roasted Cuban coffee beans to ensure the best flavor.

– **Grind Adjustment**: Adjust the coarseness of the coffee grounds according to the drip extraction method to achieve ideal results.

– **Cleaning and Maintenance**: Regularly clean the machine, especially the filter area, to prevent residue buildup affecting subsequent use.

#### V. Market Trends and Future Outlook

1. **Market Trends**

– With increasing consumer demand for high-quality coffee, the market for drip coffee packaging machines is growing, particularly in the premium coffee sector.

2. **Technological Innovations**

– Future advancements may integrate intelligent features into drip packaging machines, such as automatic coffee type recognition and smart parameter adjustments.

3. **Sustainability**

– Heightened environmental awareness is driving manufacturers to develop more energy-efficient and recyclable packaging materials, promoting sustainable industry practices.

#### VI. Conclusion

Cuban coffee, with its unique flavor and high quality, holds a significant position in global markets. Drip coffee packaging machines, as effective extraction and packaging tools, excel at preserving coffee’s flavor and freshness. Their combination not only elevates product quality but also enhances consumer coffee experiences. For businesses and individuals entering this field, understanding market demands and technological developments is crucial for success.

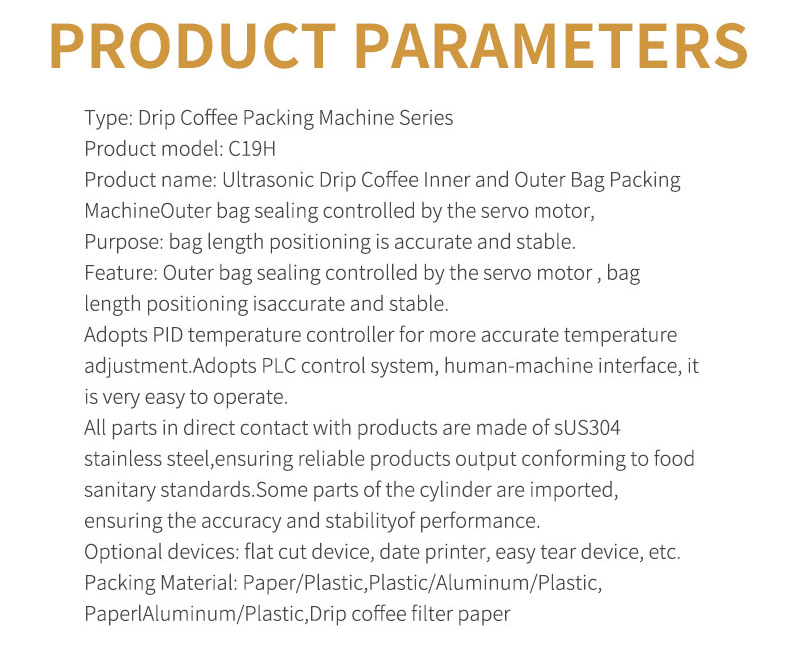

Type: Drip Coffee Packing Machine Series

Product model: C19H

Product name: Ultrasonic Drip Coffee Inner and Outer Bag Packing MachineOuter bag sealing controlled by the servo motor,

Purpose: bag length positioning is accurate and stable.

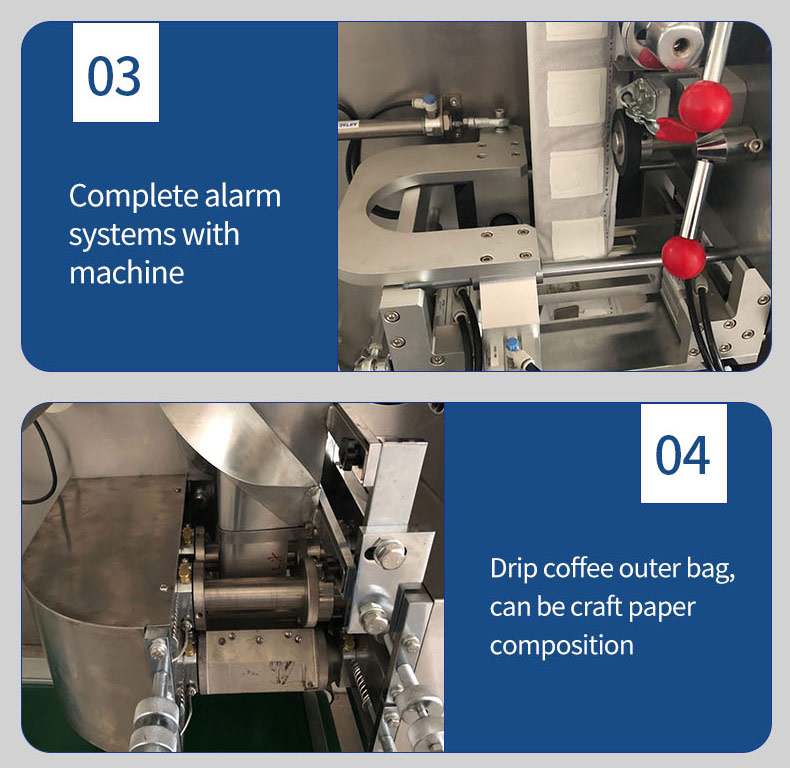

Feature: Outer bag sealing controlled by the servo motor , bag length positioning isaccurate and stable.

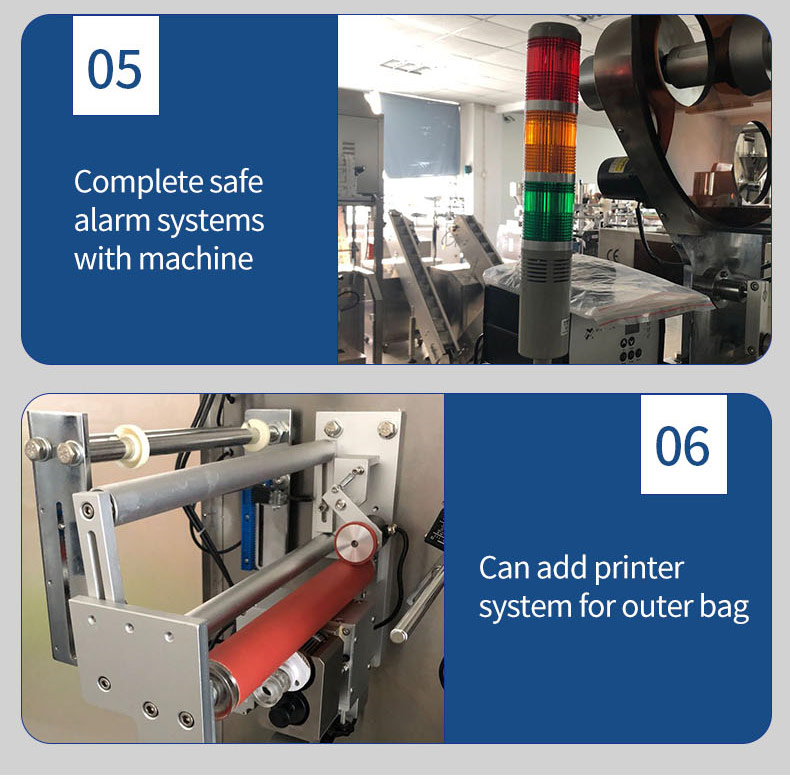

Adopts PID temperature controller for more accurate temperature adjustment.Adopts PLC control system, human-machine interface, it is very easy to operate.

All parts in direct contact with products are made of sUS304 stainless steel,ensuring reliable products output conforming to food sanitary standards.Some parts of the cylinder are imported, ensuring the accuracy and stabilityof performance.

Optional devices: flat cut device, date printer, easy tear device, etc.

Packing Material: Paper/Plastic,Plastic/Aluminum/Plastic,PaperlAluminum/Plastic,Drip coffee filter paper

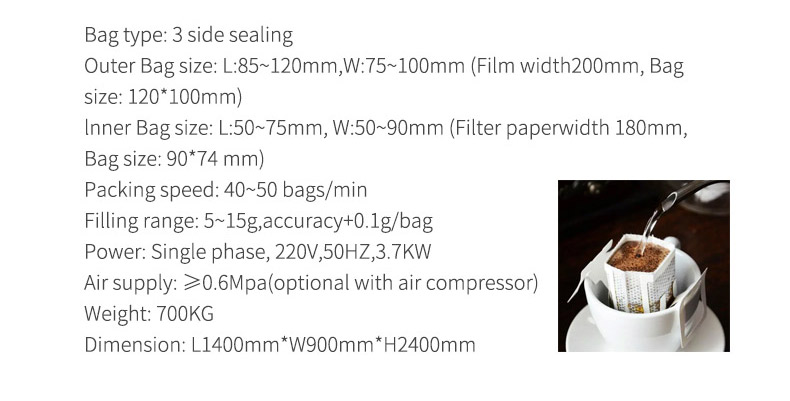

Bag type: 3 side sealing

Outer Bag size: L:85~120mm,W:75~100mm (Film width200mm, Bag size: 120*100mm)

lnner Bag size: L:50~75mm, W:50~90mm (Filter paperwidth 180mm, Bag size: 90*74 mm)

Packing speed: 40~50 bags/min

Filling range: 5~15g,accuracy+0.1g/bag

Power: Single phase, 220V,50HZ,3.7KW

Air supply: ≥0.6Mpa(optional with air compressor)

Weight: 700KG

Dimension: L1400mm*W900mm*H2400mm