Pyramid Tea Bag Packaging Machine: Precision Engineering for Premium Tea Packaging

Pyramid tea bags have gained global popularity for their enhanced flavor extraction and aesthetic appeal. For tea producers in Peru and worldwide, investing in a high-quality pyramid tea bag packaging machine is critical to maintaining competitiveness. This article explores the technical specifications, benefits, and applications of these machines, supported by verified industry data.

Key Features of Pyramid Tea Bag Packaging Machines

Advanced Automation

Modern machines like the Penglai Pack Pyramid Tea Bag Packaging Machine automate the entire process, from filling to sealing. These systems handle 30–40 bags per minute, ensuring high throughput while maintaining precision. The PLC-controlled interface allows easy adjustment of parameters such as bag size (inner: 50–80mm x 50–70mm; outer: 70–90mm x 70–120mm) and filling volume (1–10g).

Material Compatibility

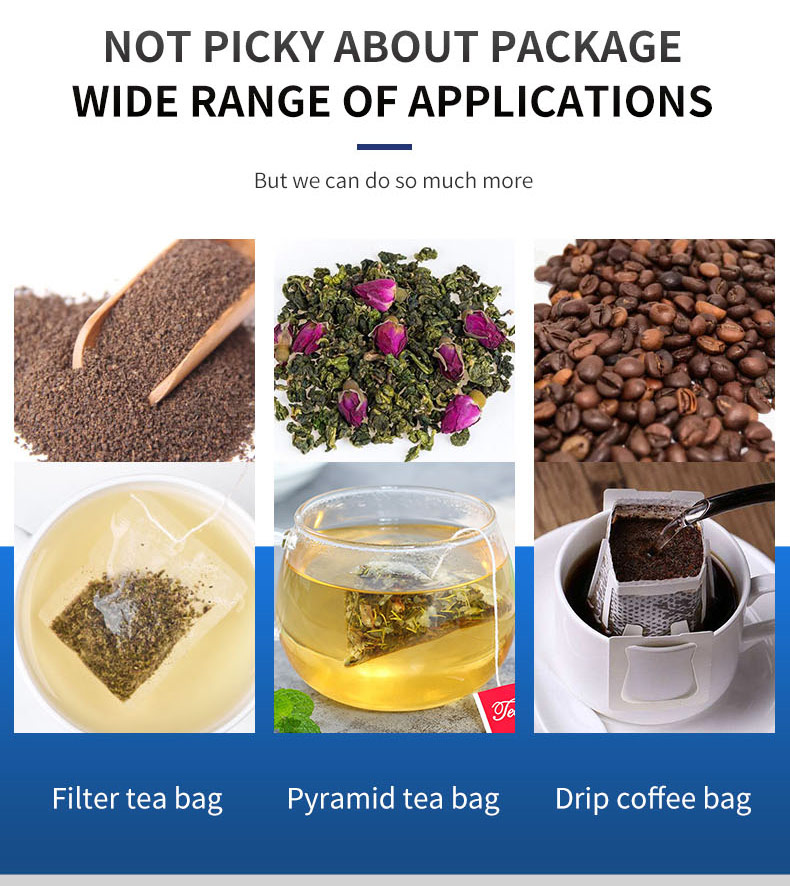

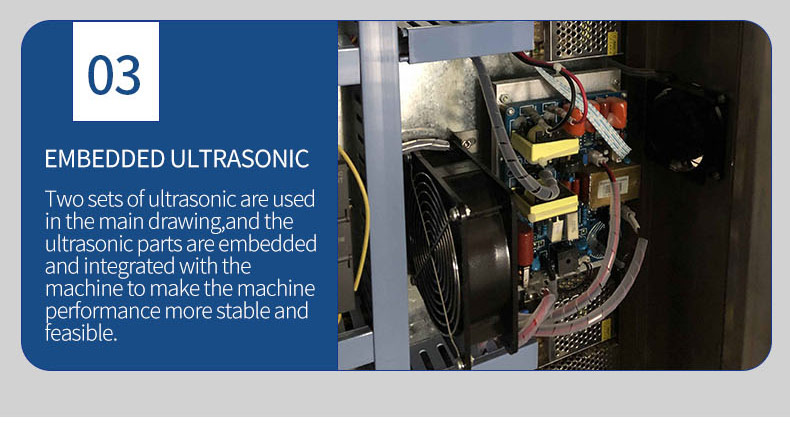

These machines support eco-friendly materials like nylon mesh and biodegradable PLA film —ideal for Peruvian organic tea brands. The ultrasonic sealing technology ensures strong, clean seals without heat distortion, preserving the tea’s aroma and quality.

Customization Options

Customizable tag and string placement cater to branding needs, while date printing and batch coding enhance traceability. Some models, like the C28DX, even allow packaging of irregularly shaped products like spices or herbal blends —a versatile solution for Peruvian tea exporters.

Energy Efficiency

Designed with stainless steel 304 components, these machines operate at 220V/50Hz with low power consumption (3kW) . Their compact footprint (900x650x2300mm) suits small-to-medium production facilities.

Applications in the Peruvian Tea Industry

Peru’s tea sector, renowned for its organic yerba mate and herbal blends, benefits from pyramid packaging machines in several ways:

Flavor Enhancement: The pyramid shape allows leaves to expand fully, maximizing flavor extraction during brewing.

Market Appeal: Premium packaging aligns with global trends for artisanal tea products.

Cost Efficiency: High-speed machines reduce labor costs and minimize material waste.

Top Supplier Insights

Leading manufacturers such as Foshan Dession Packaging Machinery and Penglai Pack offer customized solutions for Peruvian producers . Key considerations when selecting a supplier include:

Customization: Ensure the machine accommodates your specific tea type (e.g., loose-leaf, powdered, or herbal blends).

Certifications: Verify compliance with international food safety standards (e.g., FDA, CE).

Maintenance Tips for Optimal Performance

Regularly clean ultrasonic sealing bars to prevent residue buildup.

Calibrate filling mechanisms monthly to maintain accuracy.

Store spare parts locally to avoid downtime during repairs.

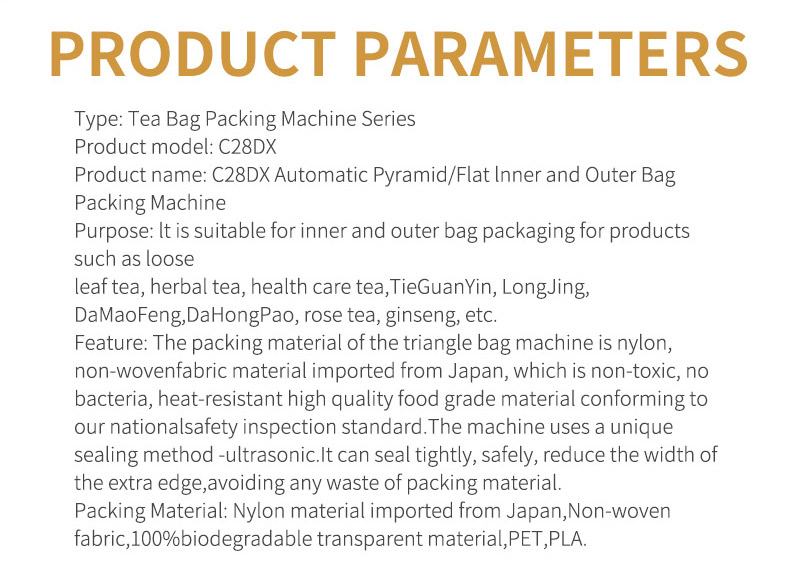

Type: Tea Bag Packing Machine Series

Product model: C28DX

Product name: C28DX Automatic Pyramid/Flat lnner and Outer Bag Packing Machine

Purpose: lt is suitable for inner and outer bag packaging for products such as loose

leaf tea, herbal tea, health care tea,TieGuanYin, LongJing, DaMaoFeng,DaHongPao, rose tea, ginseng, etc.

Feature: The packing material of the triangle bag machine is nylon, non-wovenfabric material imported from Japan, which is non-toxic, no bacteria, heat-resistant high quality food grade material conforming to our nationalsafety inspection standard.The machine uses a unique sealing method -ultrasonic.It can seal tightly, safely, reduce the width of the extra edge,avoiding any waste of packing material.

Packing Material: Nylon material imported from Japan,Non-woven fabric,100%biodegradable transparent material,PET,PLA.

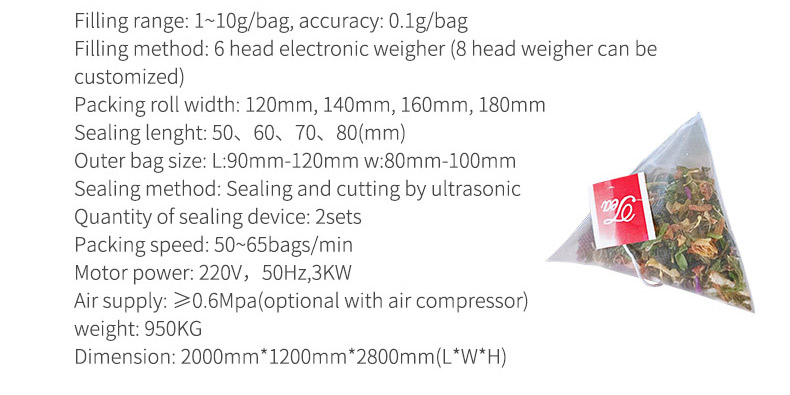

Filling range: 1~10g/bag, accuracy: 0.1g/bag

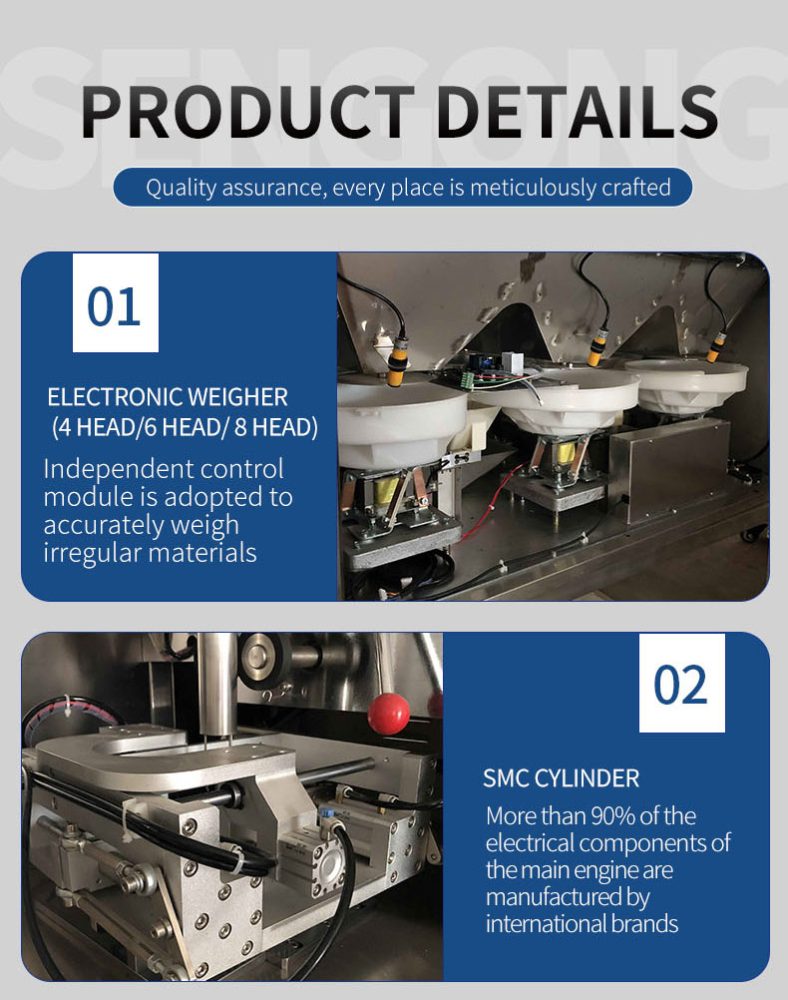

Filling method: 6 head electronic weigher (8 head weigher can be customized)

Packing roll width: 120mm, 140mm, 160mm, 180mm

Sealing lenght: 50、60、70、80(mm)

Outer bag size: L:90mm-120mm w:80mm-100mm

Sealing method: Sealing and cutting by ultrasonic

Quantity of sealing device: 2sets

Packing speed: 50~65bags/min

Motor power: 220V,50Hz,3KW

Air supply: ≥0.6Mpa(optional with air compressor)

weight: 950KG

Dimension: 2000mm*1200mm*2800mm(L*W*H)