Explore high-speed automatic drip coffee bag packaging machines designed for Thailand and Southeast Asian markets. This PLC-controlled equipment supports 30-70 bags/min with customizable sizes (50-120mm), ideal for filter coffee, tea, and herbal products. Features ultrasonic sealing, nitrogen filling, and multi-language interfaces for hygienic, efficient packaging. Compatible with biodegradable PLA materials and kraft paper composites. OEM services available. Trusted by suppliers in Africa, Europe, and South America. 1-year warranty + lifetime support. Contact verified manufacturers for quotes!

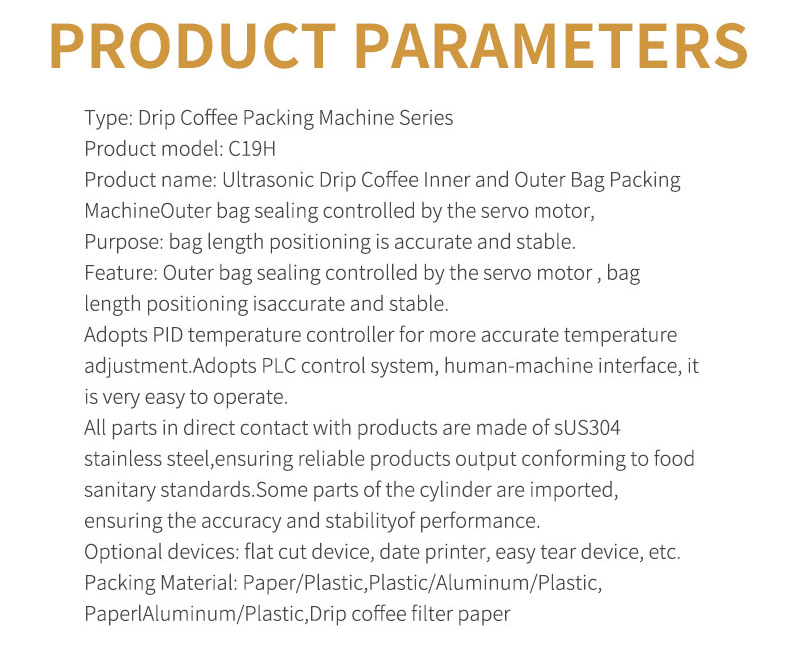

Type: Drip Coffee Packing Machine Series

Product model: C19H

Product name: Ultrasonic Drip Coffee Inner and Outer Bag Packing MachineOuter bag sealing controlled by the servo motor,

Purpose: bag length positioning is accurate and stable.

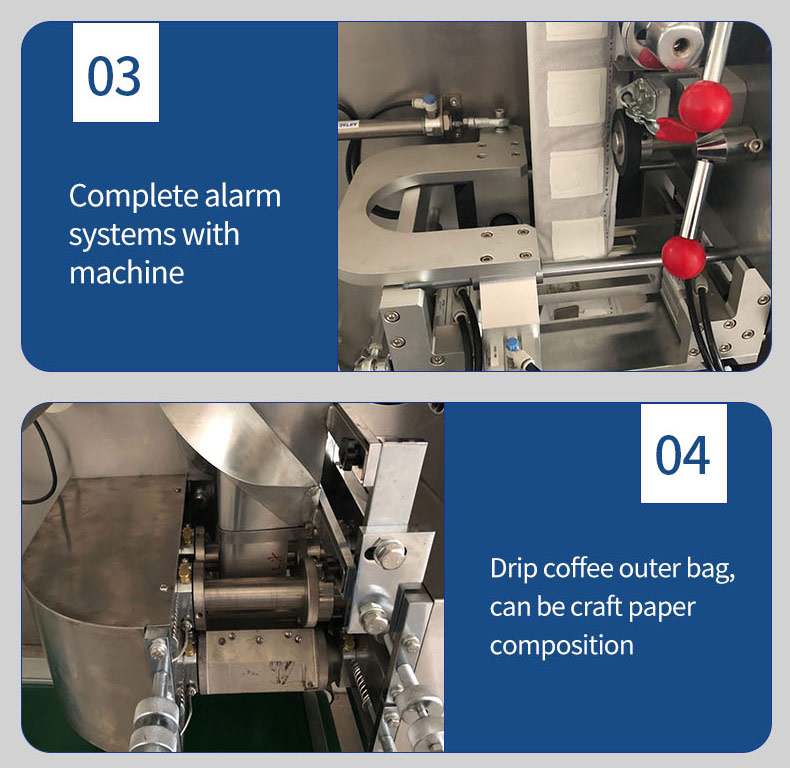

Feature: Outer bag sealing controlled by the servo motor , bag length positioning isaccurate and stable.

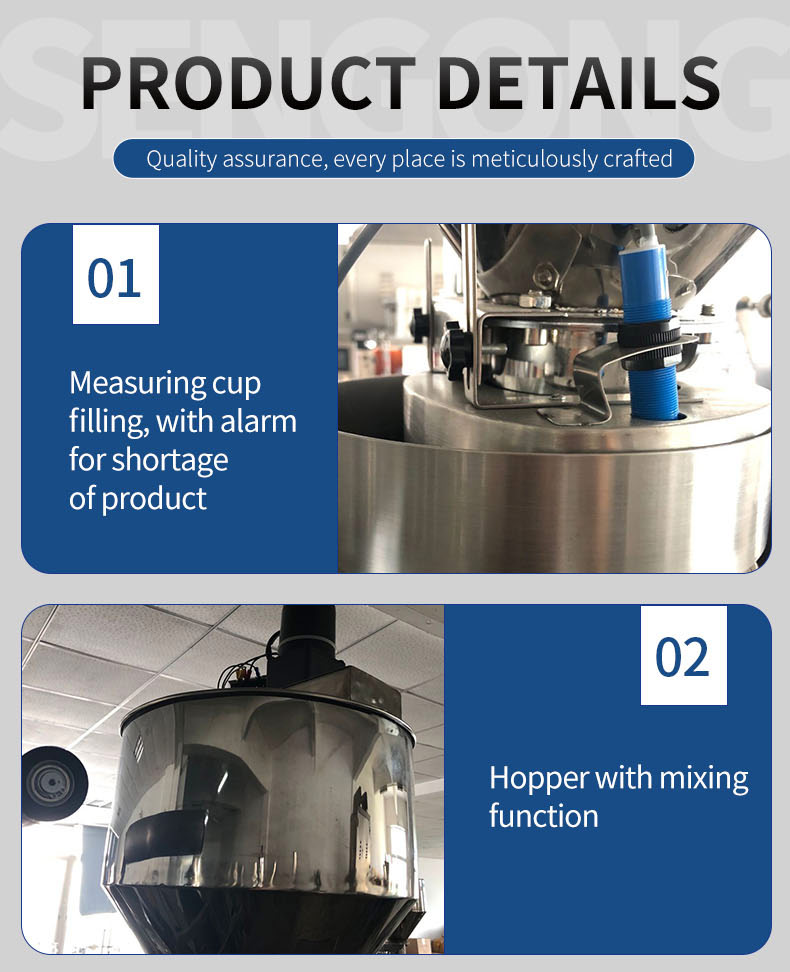

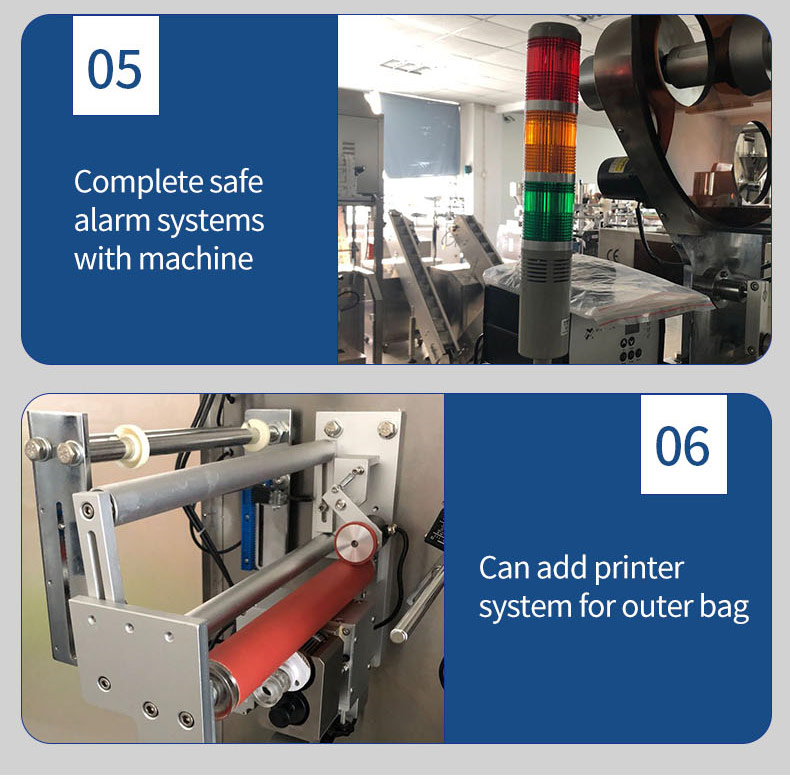

Adopts PID temperature controller for more accurate temperature adjustment.Adopts PLC control system, human-machine interface, it is very easy to operate.

All parts in direct contact with products are made of sUS304 stainless steel,ensuring reliable products output conforming to food sanitary standards.Some parts of the cylinder are imported, ensuring the accuracy and stabilityof performance.

Optional devices: flat cut device, date printer, easy tear device, etc.

Packing Material: Paper/Plastic,Plastic/Aluminum/Plastic,PaperlAluminum/Plastic,Drip coffee filter paper

Bag type: 3 side sealing

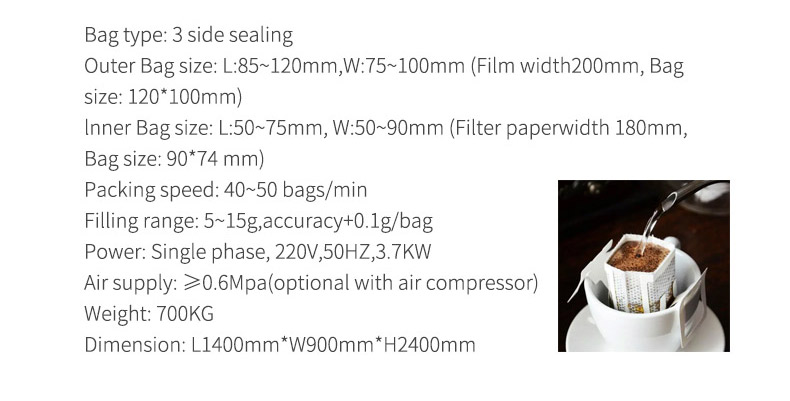

Outer Bag size: L:85~120mm,W:75~100mm (Film width200mm, Bag size: 120*100mm)

lnner Bag size: L:50~75mm, W:50~90mm (Filter paperwidth 180mm, Bag size: 90*74 mm)

Packing speed: 40~50 bags/min

Filling range: 5~15g,accuracy+0.1g/bag

Power: Single phase, 220V,50HZ,3.7KW

Air supply: ≥0.6Mpa(optional with air compressor)

Weight: 700KG

Dimension: L1400mm*W900mm*H2400mm