The crop first arrived in Brazil in the 18th century, and the country had become the dominant producer by the 1840s. Brazilian coffee prospered since the early 19th century, when immigrants came to work in the coffee plantations. Production as a share of world coffee output peaked in the 1920s but has declined since the 1950s due to increased global production.

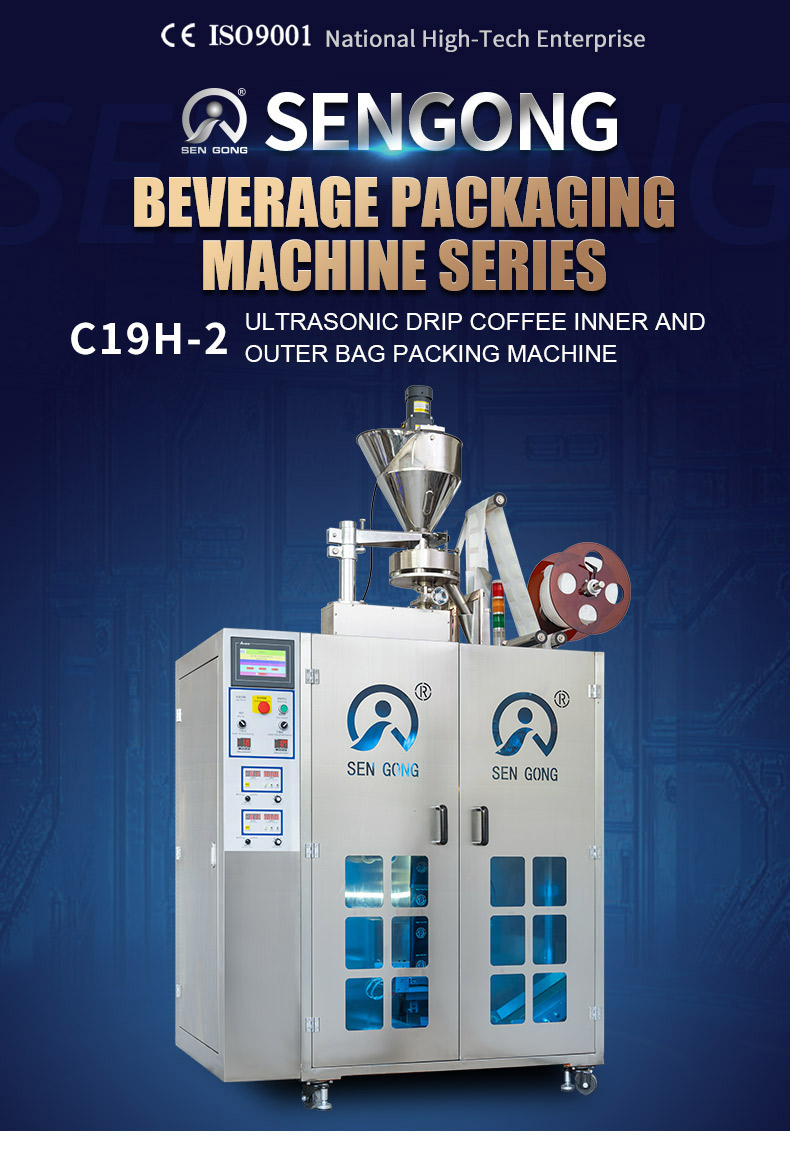

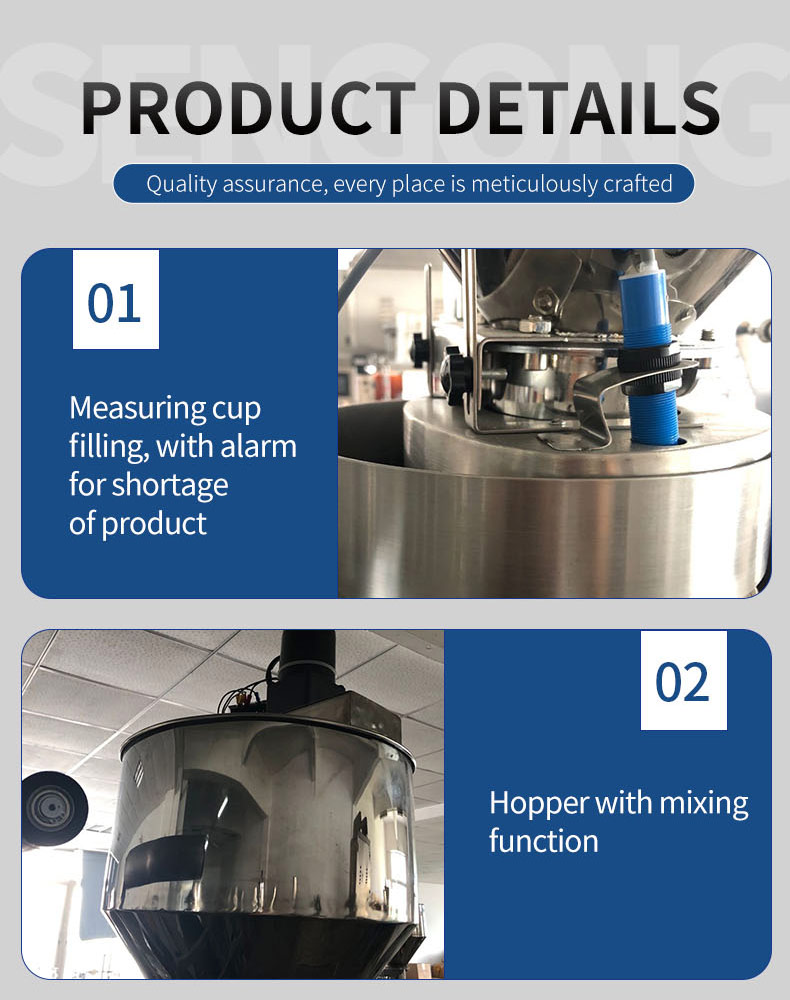

C19H-2 Automatic Ultrasonic Drip Coffee Bag Packing Machine

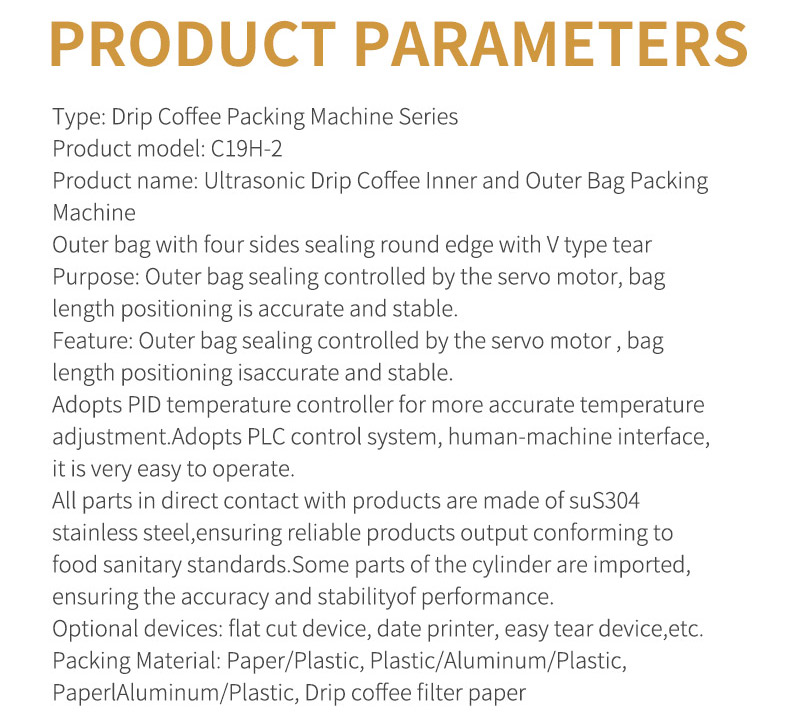

Type: Drip Coffee Packing Machine Series

Product model: C19H-2

Product name: Ultrasonic Drip Coffee Inner and Outer Bag Packing Machine

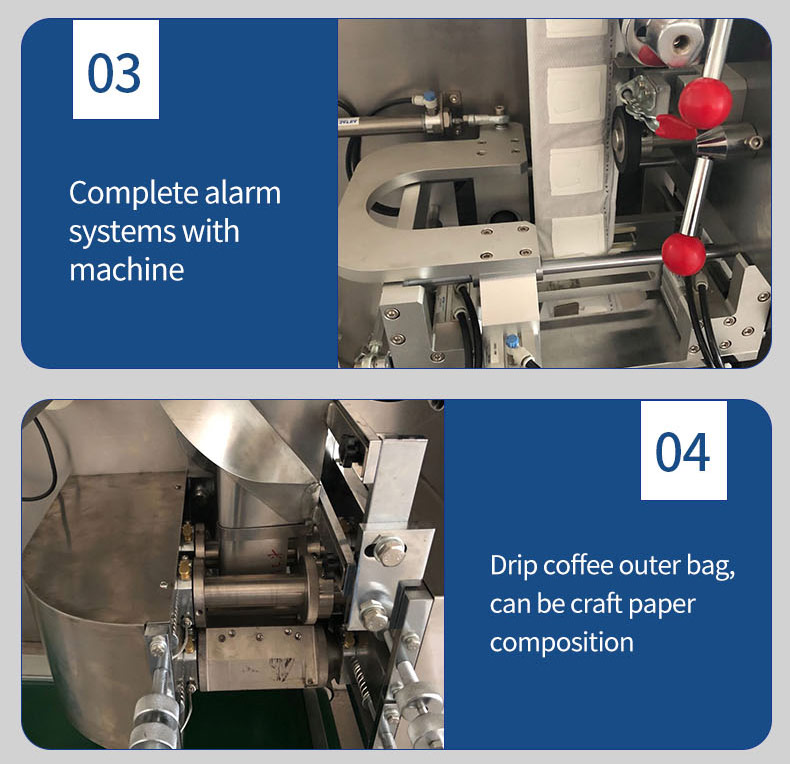

Outer bag with four sides sealing round edge with V type tear

Purpose: Outer bag sealing controlled by the servo motor, bag length positioning is accurate and stable.

Feature: Outer bag sealing controlled by the servo motor , bag length positioning isaccurate and stable.

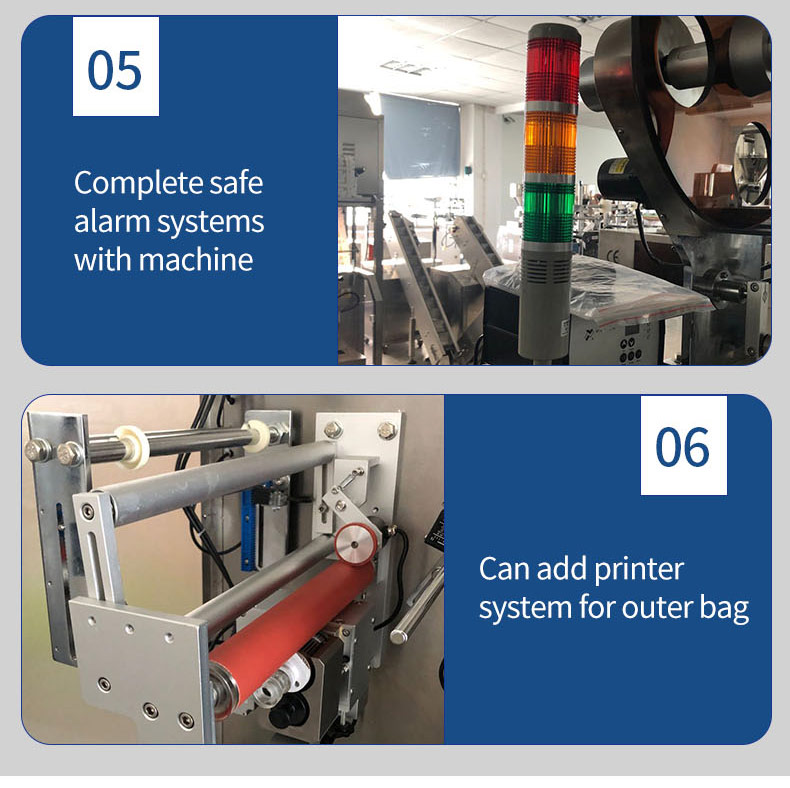

Adopts PID temperature controller for more accurate temperature adjustment.Adopts PLC control system, human-machine interface, it is very easy to operate.

All parts in direct contact with products are made of suS304 stainless steel,ensuring reliable products output conforming to food sanitary standards.Some parts of the cylinder are imported, ensuring the accuracy and stabilityof performance.

Optional devices: flat cut device, date printer, easy tear device,etc.

Packing Material: Paper/Plastic, Plastic/Aluminum/Plastic, PaperlAluminum/Plastic, Drip coffee filter paper

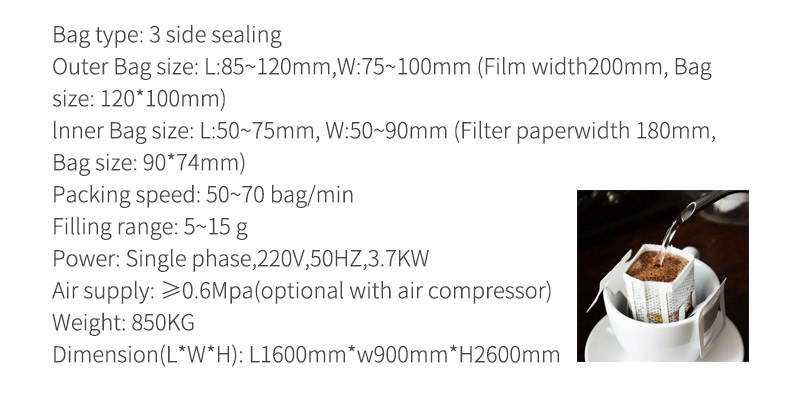

Bag type: 3 side sealing

Outer Bag size: L:85~120mm,W:75~100mm (Film width200mm, Bag size: 120*100mm)

lnner Bag size: L:50~75mm, W:50~90mm (Filter paperwidth 180mm, Bag size: 90*74mm)

Packing speed: 50~70 bag/min

Filling range: 5~15 g

Power: Single phase,220V,50HZ,3.7KW

Air supply: ≥0.6Mpa(optional with air compressor)

Weight: 850KG

Dimension(L*W*H): L1600mm*w900mm*H2600mm