From discovery to popular world, teabags are also in a process of continuous improvement. Compared with previous teabags, teabags are more interesting and convenient in appearance and use. The material of teabags There are many improvements and enrichments in tea, shape and tea types.

First of all, the material of the small tea bag was improved from silk at the beginning to gauze cloth woven from silk floss later. Until 1930, there was another leap in the development of tea bags in terms of materials – American William Hermansson obtained the patent right for heat-sealed paper tea bags. This design process is still in use today.

Pyramid tea bag filling machine

C28DX Automatic Nylon Pyramid/Flat Inner and Outer Bag Packing Machine

l Application:

It is suitable for inner and outer teabag packaging for products such as loose leaf tea,

herbal tea, health care tea, flower tea, and Chinese local tea like Darjeeling, Assam,

Ceylon, etc.

l Features:

1. The packing material of the triangle packaging bag is nylon, non-woven fabric imported

from Japan, which is non-toxic, non-bacteria, heat-resistant and high quality food-grade

material, conforming to our national safety inspection standard.

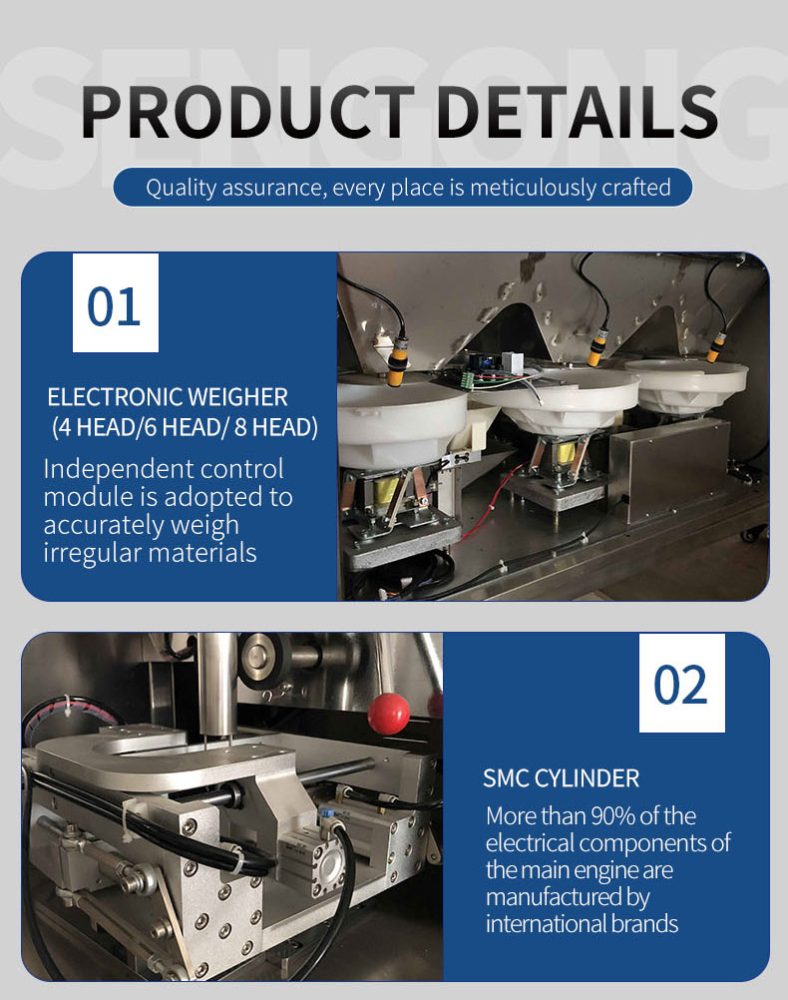

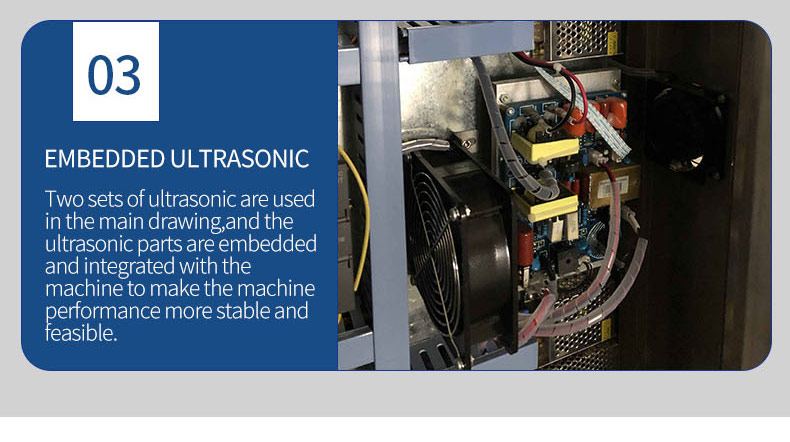

2. The machine uses a unique sealing method–ultrasonic. It can seal tightly, safely, and

reduce the width of the extra edge, avoiding any waste of packing materials.

l Technical data:

Machine type: Tea Bag Packing Machine Series

Machine Model: C28DX

Machine name: C28DX Automatic Nylon Pyramid/Flat Inner and Outer Bag Packing Machine

Packing speed: 30~50bags/min

Filling range: 1~10g

Accuracy: ±0.1g/bag

Packing roll width: 140, 160, 180(mm)

Outer bag size: W:80-100mm, L: 90-120mm

Sealing method: Cutting and sealing by ultrasonic

Quantity of seal device: 2sets

Power supply: 220V , 50Hz, 1.85KW

Air supply: 0.6MPa (can be quipped with air compressor)

Dimensions: 3000*900*2350mm(L*W*H)

Machine weight: 700KGS