Australia Pyramid Tea Bag Packaging Machine: Advanced Solutions for Premium Tea Brands

For tea manufacturers and suppliers targeting Australia’s growing specialty tea market, investing in a pyramid tea bag packaging machine is essential to meet consumer demands for quality, convenience, and sustainability. This SEO-optimized guide highlights the features, benefits, and industry relevance of these machines for businesses aiming to dominate the Australian market.

1. Why Pyramid Tea Bags?

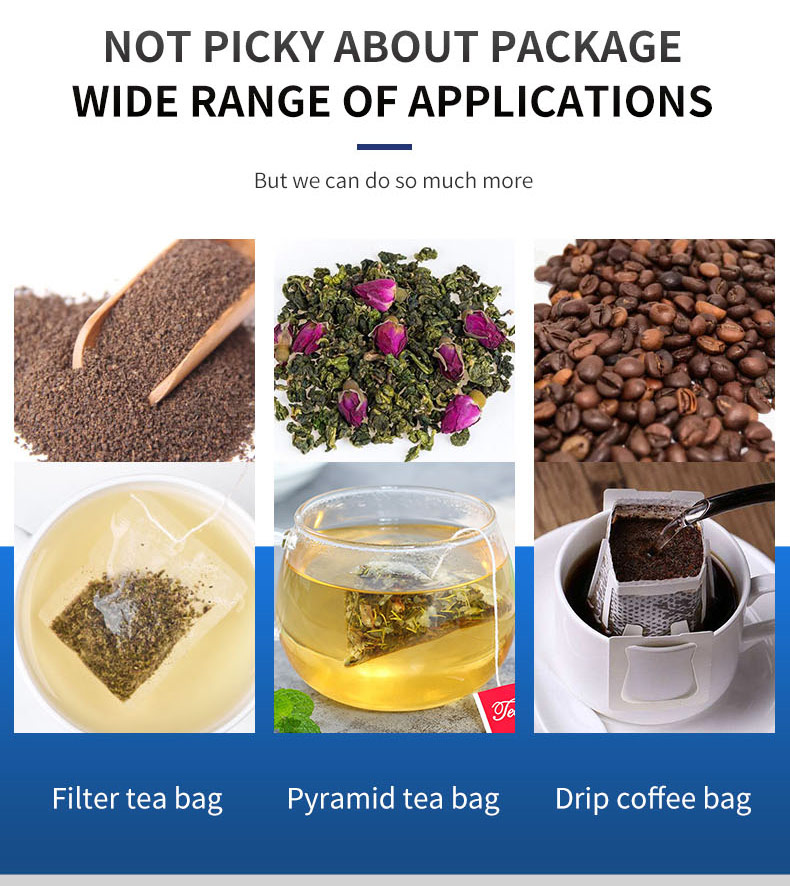

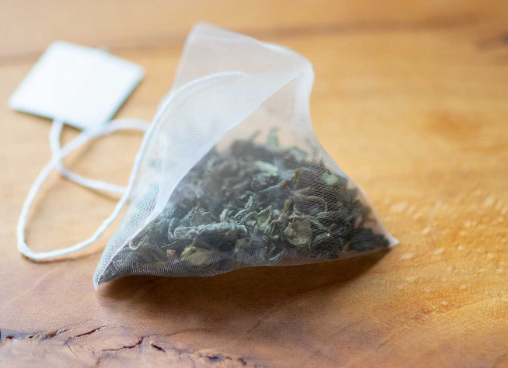

Pyramid-shaped tea bags are increasingly popular in Australia due to their ability to accommodate whole-leaf teas, herbs, and botanicals while enhancing infusion efficiency. Unlike traditional flat tea bags, pyramid designs appeal to premium tea brands seeking to differentiate their products in competitive markets like Melbourne, Sydney, and Brisbane.

2. Key Features of Modern Pyramid Tea Bag Packaging Machines

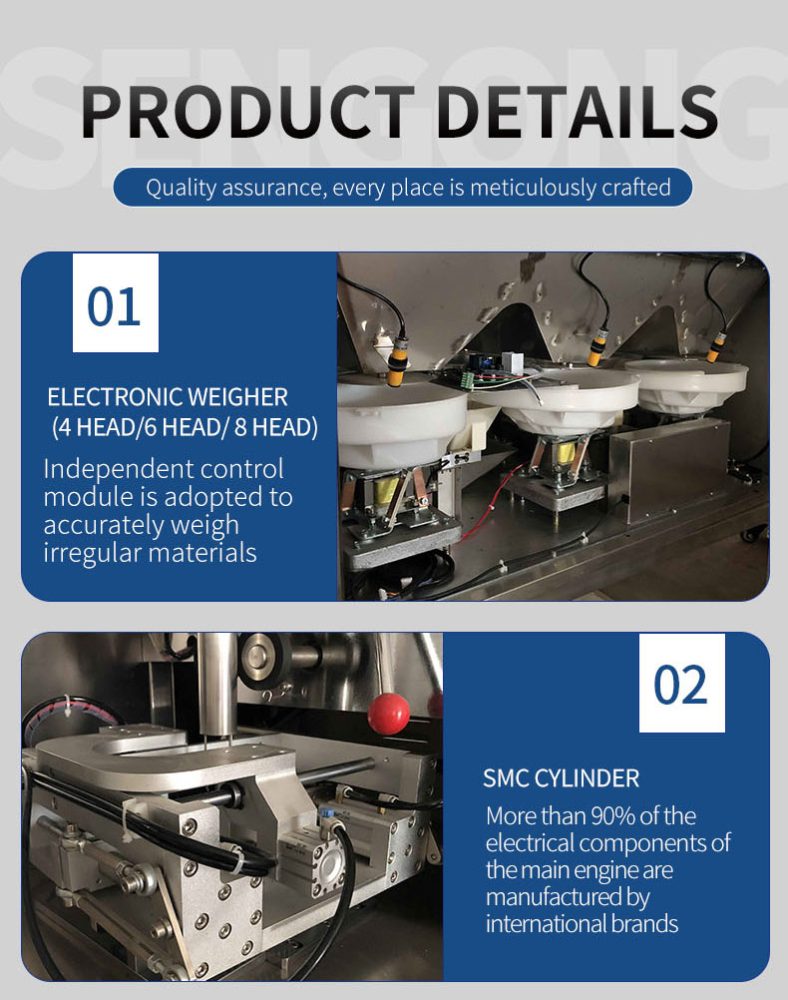

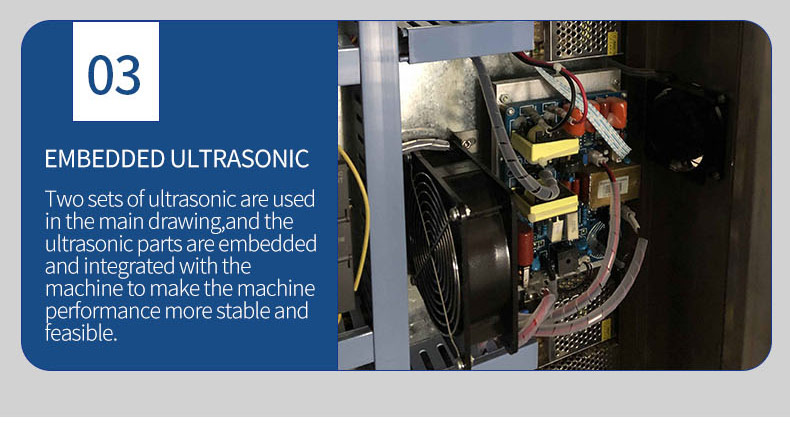

Fully Automated Operation: Advanced models, such as those from Alibaba suppliers, integrate ultrasonic sealing, precision cutting, and servo-driven filling systems to ensure consistent quality and high-speed production (up to 50 bags/minute).

Customizable Packaging: Machines support diverse materials, including nylon mesh, biodegradable filter paper, and eco-friendly PLA, aligning with Australia’s sustainability trends.

Smart Technology: Touchscreen interfaces and PLC controls allow easy adjustments for bag size, thread attachment, and tag printing—critical for private-label brands requiring flexible branding.

3. Compliance with Australian Standards

Leading machines adhere to strict food safety regulations (e.g., HACCP, ISO 22000) and are built from stainless steel (Grade 304) for durability and hygiene. This compliance is vital for exporters targeting Australia’s rigorous import standards.

4. Applications Across Tea Varieties

These machines cater to:

Loose-Leaf Blends: Ideal for Australian favorites like lemon myrtle, ginger-infused green tea, or native bush teas.

Functional Teas: Efficiently pack detox blends, herbal infusions, or CBD teas with precision dosing.

Gourmet and Gift Packaging: Options for foil-lined pouches, cartons, or biodegradable sachets enhance shelf appeal.

5. Why Source from Trusted Suppliers?

Australia’s tea industry relies on imported machinery from certified manufacturers in China, Germany, and Japan. Key suppliers on Alibaba and TradeKey offer after-sales support, OEM customization, and cost-effective solutions tailored to small and large-scale producers.

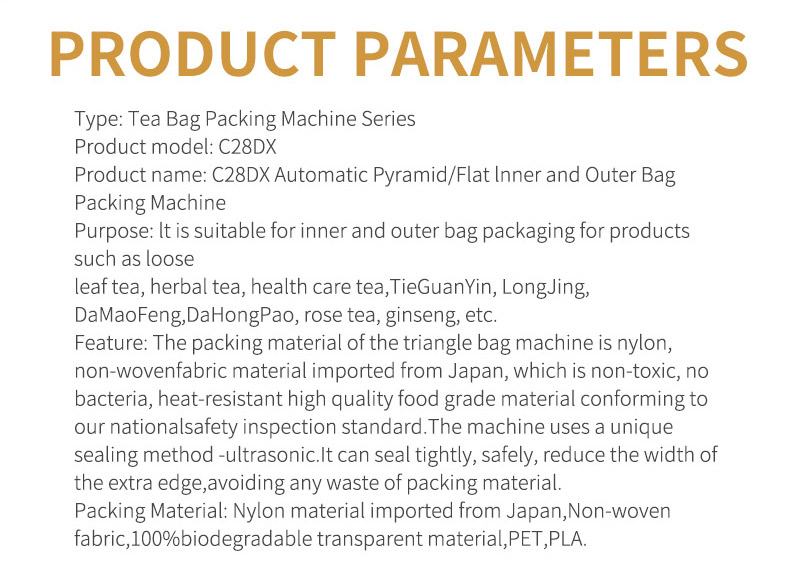

Type: Tea Bag Packing Machine Series

Product model: C28DX

Product name: C28DX Automatic Pyramid/Flat lnner and Outer Bag Packing Machine

Purpose: lt is suitable for inner and outer bag packaging for products such as loose

leaf tea, herbal tea, health care tea,TieGuanYin, LongJing, DaMaoFeng,DaHongPao, rose tea, ginseng, etc.

Feature: The packing material of the triangle bag machine is nylon, non-wovenfabric material imported from Japan, which is non-toxic, no bacteria, heat-resistant high quality food grade material conforming to our nationalsafety inspection standard.The machine uses a unique sealing method -ultrasonic.It can seal tightly, safely, reduce the width of the extra edge,avoiding any waste of packing material.

Packing Material: Nylon material imported from Japan,Non-woven fabric,100%biodegradable transparent material,PET,PLA.

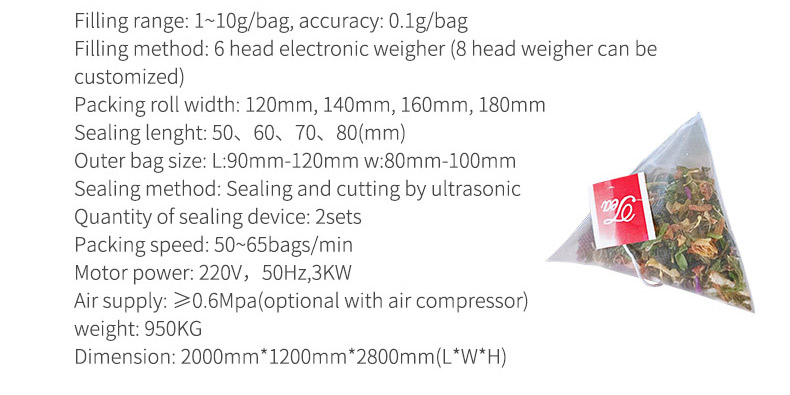

Filling range: 1~10g/bag, accuracy: 0.1g/bag

Filling method: 6 head electronic weigher (8 head weigher can be customized)

Packing roll width: 120mm, 140mm, 160mm, 180mm

Sealing lenght: 50、60、70、80(mm)

Outer bag size: L:90mm-120mm w:80mm-100mm

Sealing method: Sealing and cutting by ultrasonic

Quantity of sealing device: 2sets

Packing speed: 50~65bags/min

Motor power: 220V,50Hz,3KW

Air supply: ≥0.6Mpa(optional with air compressor)

weight: 950KG

Dimension: 2000mm*1200mm*2800mm(L*W*H)